Garment Industry – Clothes Folding Machine

Discover the significance of India’s garment markets, including Surat Textile Market, Gandhinagar Market, and Mega Textile Park. Learn about the evolution and benefits of clothes folding machines in enhancing efficiency, reducing labor costs, and maintaining uniformity in wholesale cloth markets like Chandni Chowk and Crawford Market. Explore case studies and future prospects for technological advancements in the textile industry.

From ₹2,999.00

Additional information

| Weight | 2.366 kg |

|---|---|

| Dimensions | 30 × 10 × 9 cm |

| SOLD BY | ImStarTrading (IST) |

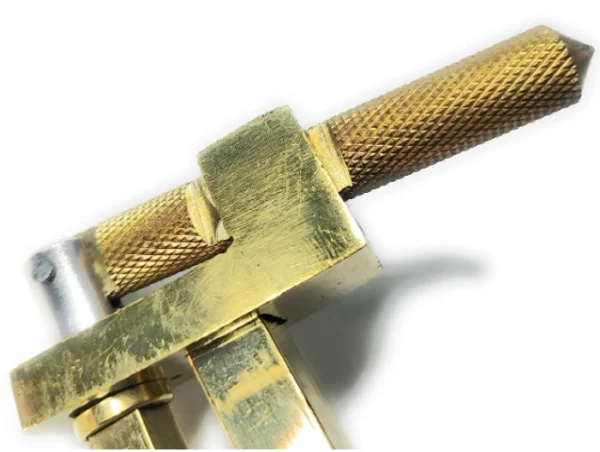

| COLOUR | Gold |

| MATERIAL | Brass |

| GSM RANGE OF FOLDED CLOTH | 100 to 200 GSM* |

| TYPE | Gauge |

| PACK OF | 2pc |

| GENERIC NAME | Cloth Folder Meter |

| MADE IN | India |

| DEPARTMENT | Used in textile factories for making rolls of cloth or fabric. Silk, Chiffon, Linen, Cotton, Denim, Georgette, Chintz, Calico, Cheesecloth, Rayon, Crepe, Cotton Fabric, Muslin, Woolen, Satin, Batik, Corduroy, Khadi, Cambric, Kashmiri, Leather, Polyester, Velvet, Banaras Silk, Rexine, Terrycot Fabric, Net Fabric, Choli Fabric, Curtain Fabric, Curtain Fabric, Saree, Poplin, Plain, Kurtis, Suits, Rayon, Knitted, Hosiery, Petticoat, Dupatta, Hijab, Plain Fabric, Nighi, Shirt Fabric, Digital Designer Fabric, Inserts, Boutique Fabric, Blouses, Export Fabric, Kurtis, Tops, Kurtas, Ajrakh Fabric, Jute Fabric, Linen Fabric, Lycra, T-Shirt Fabric, Dhoti, Lungi, Dhoti and Handicrafts This manual fabric folding machine is perfect for all your fabric folding needs. |

Introduction to India’s Garment Markets

India’s garment markets are globally recognized for their vast scale, diversity, and economic significance. As a cornerstone of the global textile industry, these markets facilitate the trade of millions of garments annually, catering to both domestic and international demands. Among the myriad of textile hubs, Surat Textile Market, Gandhinagar Market, and Mega Textile Park stand out for their extensive reach and influence.

Surat Textile Market, located in Gujarat, is often referred to as the ‘Silk City of India.’ This market is renowned for its production of synthetic textiles, including saris and dress materials, which are distributed nationwide and exported worldwide. The Surat Textile Market is a bustling hub, characterized by its vibrant trade activities and a wide array of textile goods. Its significance in the garment sector cannot be overstated, as it plays a pivotal role in setting trends and driving the textile economy.

Gandhinagar Market, also situated in Gujarat, is another key player in India’s garment industry. This market specializes in traditional Indian wear, including lehengas, kurtis, and bridal attire. Its reputation for quality craftsmanship and intricate designs has made it a preferred destination for retailers and wholesalers alike. The Gandhinagar Market’s contribution to preserving and promoting India’s rich cultural heritage through textiles is commendable.

The Mega Textile Park, a relatively recent addition, represents the future of India’s garment industry. Strategically designed to integrate advanced technologies and sustainable practices, this park aims to enhance productivity and minimize environmental impact. It serves as a model for modern textile manufacturing, emphasizing the importance of innovation in maintaining India’s competitive edge in the global market.

These markets collectively underscore India’s prominent role in the textile industry. They set the stage for understanding how technological advancements, such as clothes folding machines, can revolutionize garment production and distribution, ultimately enhancing efficiency and profitability in India’s wholesale cloth markets.

The Evolution of Clothes Folding Machines

The history of clothes folding machines is a fascinating journey marked by technological innovation and industrial advancement. Initially, the concept of mechanized clothes folding emerged in the early 20th century, driven by the need to streamline labor-intensive processes in garment manufacturing. These early machines were rudimentary, relying heavily on manual intervention and producing inconsistent results. However, they laid the groundwork for future advancements in the field.

As the textile industry expanded, so did the demand for more efficient and reliable folding solutions. The mid-20th century saw significant improvements with the integration of automated systems. These machines, equipped with simple mechanical arms and rollers, began to offer enhanced speed and better consistency. This period marked the beginning of a more systematic approach to clothes folding, significantly reducing the manual labor required in the garment industry.

The advent of digital technology in the late 20th and early 21st centuries brought about a revolution in the design and functionality of clothes folding machines. Modern-day machines are equipped with sophisticated sensors and computer algorithms, allowing for precise folding techniques tailored to various types of fabrics and garments. These advancements have not only increased the speed and efficiency of the folding process but also improved the quality and uniformity of the finished products.

Today’s clothes folding machines are marvels of engineering, capable of processing thousands of garments per hour with minimal human intervention. They incorporate advanced features such as adjustable folding patterns, real-time monitoring systems, and smart interfaces that allow operators to customize settings to meet specific requirements. This evolution reflects the broader trend in the textile industry towards automation and smart manufacturing, aiming to meet the growing demands of global markets.

In summary, the evolution of clothes folding machines from rudimentary mechanical devices to highly sophisticated automated systems highlights the relentless pursuit of efficiency and quality in the garment industry. As these technologies continue to advance, they promise to further transform wholesale cloth markets, particularly in burgeoning economies like India, where the demand for efficient textile processing solutions is ever-increasing.

Benefits of Clothes Folding Machines in Wholesale Cloth Markets

The integration of clothes folding machines in India’s wholesale cloth markets, such as Chandni Chowk, Nehru Place, and Karol Bagh Market, presents numerous advantages that substantially enhance operational efficiencies. One of the primary benefits is the significant improvement in efficiency. Traditional manual folding is time-consuming and prone to human error, whereas automated folding machines streamline the process, enabling faster turnover of inventory. This efficiency is crucial in bustling wholesale environments where time and precision are paramount.

Another substantial benefit is the reduction in labor costs. Employing manual labor for folding garments not only requires a sizeable workforce but also involves ongoing training and supervision. Clothes folding machines mitigate these expenses by reducing the need for manual intervention, allowing businesses to allocate human resources to other critical areas such as customer service and sales. This shift not only curbs operational costs but also optimizes the workforce for more value-added tasks.

Uniformity in folding is another compelling advantage of using clothes folding machines. In wholesale markets where large volumes of garments are handled daily, consistency is key. Automated folding ensures that every piece of clothing is folded to the same standard, enhancing the overall presentation and appeal of the products. This uniformity is particularly beneficial for retailers who rely on a neat and organized display to attract customers and facilitate easier inventory management.

Moreover, the overall productivity of wholesale cloth markets is significantly enhanced with the deployment of clothes folding machines. By automating the folding process, businesses can handle larger volumes of garments with greater speed and accuracy. This boost in productivity not only meets the high demand in busy markets but also positions businesses to scale operations more efficiently. As a result, markets like Chandni Chowk, Nehru Place, and Karol Bagh can sustain their competitive edge in the rapidly evolving garment industry.

Case Studies: Implementation in Key Markets

The integration of clothes folding machines in India’s wholesale cloth markets has marked a significant transformation in operational efficiency and productivity. Examining specific markets such as Sarojini Nagar Market, Shankar Market, and Crawford Market provides insights into the tangible benefits and challenges faced by business owners and vendors.

Sarojini Nagar Market

Sarojini Nagar Market in New Delhi, known for its bustling atmosphere and diverse range of apparel, has embraced clothes folding machines to streamline operations. Vendors reported a 30% reduction in time spent on folding garments, enabling them to focus more on customer service and inventory management. Rakesh Gupta, a long-time vendor, shared, “The clothes folding machine has been a game-changer for my business. It not only saves time but also ensures uniformity in garment presentation, which appeals to customers.”

Shankar Market

In Shankar Market, another prominent wholesale market in the heart of Delhi, the adoption of clothes folding machines has led to notable improvements in workflow. Business owners have observed a significant reduction in labor costs, as the machines handle the bulk of the folding tasks. Anita Sharma, who owns a shop in Shankar Market, stated, “With the introduction of the folding machines, my staff can now manage more tasks simultaneously. The efficiency boost has been tremendous, and we have seen a marked increase in overall productivity.”

Crawford Market

Crawford Market in Mumbai, a hub for wholesale trading, has also seen the positive impact of clothes folding machines. Vendors have praised the machines for their reliability and ease of use. According to Rajesh Patel, a trader in Crawford Market, “Implementing clothes folding machines has significantly improved our daily operations. The machines are straightforward to operate and have reduced the physical strain on our workers. This has resulted in a happier workforce and better service for our customers.”

These case studies from Sarojini Nagar Market, Shankar Market, and Crawford Market highlight the transformative impact of clothes folding machines on the wholesale cloth markets in India. The testimonials from vendors and business owners underscore the advantages of enhanced efficiency, reduced labor costs, and improved customer satisfaction.

Challenges Faced and Solutions Implemented

Integrating clothes folding machines into India’s traditional wholesale cloth markets has not been without its challenges. One of the primary obstacles has been the initial cost associated with purchasing these machines. Many small and medium-sized enterprises, which form the backbone of these markets, find the investment prohibitive. The capital outlay required for advanced technology often deters these businesses from adopting such innovations.

Another significant challenge is the training of personnel. The introduction of clothes folding machines necessitates a shift from manual labor to machine operation, requiring workers to acquire new skills. For many, this transition is daunting, creating a barrier to acceptance. Resistance to change is deeply ingrained in traditional markets where practices have remained unchanged for decades. Employees and business owners alike often exhibit reluctance towards adopting new methods, fearing disruption to their established routines.

To address these challenges, several strategies have been successfully implemented. Financial incentives, such as subsidies and low-interest loans, have been introduced to mitigate the initial costs of acquiring clothes folding machines. These financial aids make the technology more accessible to smaller businesses, encouraging wider adoption.

In terms of training, comprehensive programs have been developed to equip personnel with the necessary skills to operate the machines efficiently. These programs include hands-on training sessions, instructional manuals, and ongoing support to ensure a smooth transition. By providing adequate training, businesses can minimize the learning curve and enhance productivity.

Moreover, addressing resistance to change involves a multifaceted approach. Awareness campaigns highlighting the long-term benefits of clothes folding machines, such as increased efficiency, consistency, and cost savings, have been instrumental. Demonstrating successful case studies where businesses have thrived post-adoption helps to alleviate fears and build confidence in the new technology.

Through these solutions, the integration of clothes folding machines into India’s wholesale cloth markets is gradually overcoming initial challenges, paving the way for a more efficient and modernized industry.

The adoption of clothes folding machines in India’s wholesale cloth markets has brought about significant economic implications. In bustling markets such as Gandhi Nagar Bazaar, Mangaldas Market, and Chickpet, the introduction of these machines has fundamentally altered the landscape of local commerce. One of the most notable impacts is on pricing. By automating the folding process, businesses can significantly cut down on labor costs, which in turn allows for more competitive pricing. This reduction in operational expenses enables wholesalers to offer better prices to retailers, subsequently benefiting end consumers with lower costs.

Market competitiveness has also seen a transformation. Traditionally, the efficiency of a wholesaler was largely dependent on manual labor, which could vary widely in terms of speed and quality. The integration of clothes folding machines ensures consistency and speed, allowing businesses to handle larger volumes with greater efficiency. This enhanced capability not only contributes to maintaining a steady supply chain but also helps in meeting the increasing demand during peak seasons. Consequently, businesses that have adopted these machines are better positioned to outperform their competitors who continue to rely on manual labor.

Moreover, the overall economic growth in these regions has been positively impacted. The efficiency brought by clothes folding machines allows businesses to scale operations more effectively. Increased productivity leads to greater output, which can stimulate local economies by creating more job opportunities in other sectors such as logistics, sales, and maintenance of these machines. Additionally, the adoption of advanced technology often attracts investments, further fueling economic development.

In markets like Gandhi Nagar Bazaar, Mangaldas Market, and Chickpet, the ripple effect of adopting clothes folding machines extends beyond individual businesses. It fosters a more dynamic market environment, encourages technological innovation, and promotes sustainable economic growth. As these regions continue to evolve, the role of automation in driving economic progress becomes increasingly evident.

Future Prospects and Innovations

The future of clothes folding machines in India’s wholesale cloth markets holds immense potential for transformative advancements. As technology continues to evolve, these machines are poised to become even more sophisticated, offering a broad spectrum of capabilities that will further streamline operations in the textile industry. One of the most promising developments on the horizon is the integration of artificial intelligence (AI) and machine learning (ML) into clothes folding machines. These technologies can enable machines to learn from vast datasets, improving their precision and adaptability to various types of fabrics and folding techniques.

Moreover, the incorporation of Internet of Things (IoT) technology can significantly enhance the connectivity and efficiency of clothes folding machines. IoT-enabled machines can communicate with other devices in a textile production line, facilitating seamless coordination and real-time monitoring of the folding process. This interconnectedness can lead to more efficient workflows, reduced downtime, and increased productivity, ultimately benefiting the entire supply chain.

Another exciting innovation is the advent of robotic folding arms equipped with advanced sensors and vision systems. These robotic arms can handle delicate fabrics with exceptional care, ensuring consistent fold quality while reducing the likelihood of damage. Additionally, the use of biodegradable and sustainable materials in the construction of these machines aligns with the growing emphasis on eco-friendly practices within the garment industry.

Emerging trends such as customization and personalization are also set to shape the future of the textile market. Clothes folding machines that can adapt to specific customer requirements, such as custom folds and packaging, will cater to the increasing demand for personalized products. This adaptability can offer a competitive edge to wholesale cloth markets, allowing them to better meet the diverse needs of their clientele.

In conclusion, the future of clothes folding machines in India’s wholesale cloth markets is brimming with potential. With ongoing advancements in AI, IoT, robotics, and sustainability, these machines are set to revolutionize the textile industry, driving efficiency, precision, and innovation to unprecedented levels.

Conclusion: Transforming India’s Textile Landscape

The advent of clothes folding machines in India’s wholesale cloth markets marks a significant milestone in the evolution of the textile industry. These machines have revolutionized the way garments are handled, bringing about efficiency, consistency, and enhanced productivity. Throughout this blog post, we have explored various facets of this transformation, from operational improvements to the broader economic implications.

One of the most notable impacts of clothes folding machines is the substantial reduction in manual labor, allowing businesses to reallocate human resources to more strategic roles. This shift not only improves the overall workflow but also contributes to increased job satisfaction and employee retention. Moreover, the precision and uniformity offered by these machines ensure that each garment meets high-quality standards, thereby enhancing customer satisfaction and brand reputation.

Furthermore, the integration of clothes folding machines has led to significant time savings. Rapid processing times enable wholesalers to meet tight deadlines and manage large volumes of orders more effectively. This capability is particularly crucial in a competitive market landscape where speed and reliability can be the determining factors for success.

The economic benefits extend beyond individual businesses. By embracing advanced technology, India’s textile sector can position itself as a leader in the global market, attracting international clients and fostering economic growth. This technological adoption also paves the way for further innovations, encouraging continuous improvement and adaptation within the industry.

As we look to the future, it is clear that embracing technology is not merely an option but a necessity for staying competitive in the textile industry. Clothes folding machines exemplify how innovation can drive progress, enabling businesses to thrive in an ever-evolving market. By continuing to invest in technological advancements, India’s garment sector can ensure sustained growth, improved efficiency, and a prominent position on the world stage.

Related Products

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

- Quick View

- Select options This product has multiple variants. The options may be chosen on the product page

Question and answer

Q: What is a Brass Cloth Folder and how is it beneficial for the Textile industry?

A: A Brass Cloth Folder is a tool used in the Textile industry to efficiently fold fabrics and clothes. It helps save time and effort by providing a uniform and precise folding method, improving workflow and productivity in textile establishments.

Q: How does the Brass Cloth Folder Clip work in conjunction with the Brass Cloth Folder?

A: The Brass Cloth Folder Clip, also known as Kaata, is used to secure the fabric in place while folding with the Brass Cloth Folder. It ensures that the fabric remains in the desired position for a neat and consistent fold.

Q: Why is the Brass Cloth Folding Tool for Textiles preferred over manual folding methods?

A: The Brass Cloth Folding Tool for Textiles offers a faster and more efficient way to fold fabrics compared to manual methods. It reduces the risk of mistakes and inconsistencies in folding, leading to a more professional finish in the textile products.

Q: What are some popular brands or products in the market for Brass Clothes Folder or fabric folding machines?

A: ImStarTrading offers a range of Brass Cloth Folder products, including Cloth Folder clips, textile folding equipment, fabric folding machines, and more. The Most Popular Textile Cloth Folder Brackets and Surat Textile Folding Scale are also highly regarded in the industry.

Q: How does the Fabric Folding Machine Stand improve the functionality of a fabric folding machine?

A: The Fabric Folding Machine Stand provides stability and support for the fabric folding machine, ensuring smooth operation and preventing any disruptions during the folding process. It helps maintain the machine’s accuracy and efficiency.

Q: What are the advantages of using a Manual Textile Clothing Fabric Folding Machine?

A: A Manual Textile Clothing Fabric Folding Machine offers a cost-effective solution for small-scale textile businesses or home use. It is easy to operate, requires minimal maintenance, and provides precise and consistent fabric folding results.

Checklist for Brass Cloth Folder for Textile industry:

Checklist

1. Consider the brand reputation and reliability of ImStarTrading Brass Cloth Folder.

2. Verify the quality and durability of the Brass Cloth Folder.

3. Ensure the Brass Cloth Folder is suitable for textile industry use.

4. Check for additional features such as Brass Cloth Folder Clip and Brass Cloth Folding Tool for Textiles.

5. Look for options like Cloth Folder clips and Fabric Folding Clips for efficient cloth folding.

6. Compare prices of clothes folding machines for home and select the best option.

7. Check for fabric folding machine manufacturers and their reputation in the industry.

8. Consider the size and capacity of the Fabric Folding Machine for your specific needs.

9. Ensure the Manual Textile Clothing Fabric Folding Machine meets safety standards and regulations.

10. Check for reviews and ratings of the Most Popular Textile Cloth Folder Brackets to make an informed decision.

By following this checklist, you can make a well-informed decision when selecting a Brass Cloth Folder for your textile industry needs.

Product Review

Are you tired of spending countless hours folding fabrics and textiles by hand? Look no further than the Brass Cloth Folder for Textile industry at ImStarTrading. This revolutionary product will streamline your folding process and increase efficiency in your textile business.

The Brass Cloth Folder is designed with precision and durability in mind, featuring a sturdy brass construction that ensures long-lasting performance. The Cloth Folder Clip included in the package securely holds fabrics in place, allowing for precise and uniform folding every time.

Say goodbye to tedious manual folding with the Brass Cloth Folding Tool for Textiles. This innovative tool simplifies the folding process, saving you time and effort. The Cloth Folder clips ensure that fabrics are neatly folded without any creases or wrinkles, giving your products a professional finish.

Whether you are in the textile industry or simply looking for a reliable clothes folding machine for home use, the Brass Textile Cloth Folder is the perfect solution. With its compact design and easy-to-use features, this machine is suitable for a variety of applications.

Experience the convenience and efficiency of a fabric folding machine with the Brass Clothes Folder. Say goodbye to cumbersome manual folding and hello to a more streamlined process. The fabric double folding machine is a game-changer for textile businesses, offering a quick and efficient way to fold fabrics with precision.

The Kapda folding machine price in India is unbeatable, making it a cost-effective investment for your business. The Fabric Folding Machine Stand ensures stability and ease of use, allowing you to focus on other aspects of your operations.

Don’t waste any more time on tedious manual folding. Upgrade to a Fabric Folding Machine and experience the difference in efficiency and quality. Choose the most popular textile cloth folder brackets and take your textile business to the next level.

Invest in a textile folding machine today and revolutionize the way you fold fabrics. With the Brass Cloth Folder at ImStarTrading, you can improve productivity and efficiency in your textile business. Say goodbye to manual folding and hello to a more streamlined and efficient process.

Related searches

Brass Cloth Folder

Looking for the best Brass Cloth Folder? Find the most popular Brass Cloth Folder at ImStarTrading.com. Our Manual Fabric Folding Machine, also known as Cloth Folder or Kapde fold karne ki Machine, is perfect for all textile folding needs. With a stand and clips included, this Brass Cloth Folder is a must-have for any textile manufacturer. Shop now for the best fabric folding solution at an affordable price.

automatic fabric folding machine

Looking for an automatic fabric folding machine? Look no further than ImStarTrading.com for the best selection of Brass Cloth Folders, Manual Fabric Folding Machines, and more. Our popular Brass Cloth Folder clips are perfect for folding clothes and textiles with ease. Find the perfect fabric folding solution at the best price in India. Shop now for the most popular textile cloth folder brackets and Surat Textile Folding Scales. Don’t miss out on the top-rated textile fabric folding machines and equipment. Purchase your fabric folding machine today!

Brass Cloth Folder Clip

Looking for a reliable and efficient solution for fabric folding in your textile industry? Look no further than ImStarTrading.com for top-of-the-line Brass Cloth Folder Clip products. Our manual fabric folding machines are perfect for all your textile folding needs, with options such as Cloth Folder Kaata and Textile Folding Kata. Check out our Brass Cloth Folding Stand and Brass Cloth Folding Tool for Textiles to streamline your production process. Whether you need Clothes Folder clips, fabric double folding machines, or Kapde fold karne ki Machine, we have you covered. Trust ImStarTrading.com for all your fabric folding solutions.

Brass Cloth Folding Tool for Textiles

Looking for a reliable brass cloth folding tool for textiles? Check out ImStarTrading.com for the best selection of manual fabric folding machines, cloth folders, and textile folding kata. Our brass cloth folding stand and clips are perfect for efficiently folding clothes and fabrics. Explore our range of fabric folding solutions, including full brass cloth folders and popular brass cloth folder brackets. Find the most popular textile cloth folder options, from Surat textile folding scales to manual textile clothing fabric folding machines. Don’t miss out on the top quality brass clothes folders and textile folding equipment at ImStarTrading.com!

Brass Clothes Folder

Looking for a reliable Brass Clothes Folder for your textile business? Explore a wide range of Brass Cloth Folder options at ImStarTrading.com, including Manual Fabric Folding Machines, Textile Folding Kata, and more. Shop now for the best deals on Brass Clothes Folders and clothing fabric folding machines.

brass clothes folding machine

Looking for a high-quality brass clothes folding machine? Check out our selection of Brass Cloth Folder products at ImStarTrading.com. Our Manual Fabric Folding Machine is perfect for folding textiles with precision. Get the best Cloth Folder, Cloth Folder Kaata, and Textile Folding Kata from us. Our Brass Cloth Folding Stand and Brass Cloth Folding Tool for Textiles are industry favorites. Shop now for brass clothes folding machine and other fabric folding solutions.

Brass Textile Cloth Folder

Looking for a reliable and efficient way to fold your textiles? Check out the Brass Textile Cloth Folder at ImStarTrading.com. Our manual fabric folding machine is perfect for all your textile folding needs, whether it’s for home use or garment manufacturing. With Brass Cloth Folder Clips and stand, our Brass Cloth Folder offers a seamless folding solution. Get the most popular textile cloth folder brackets and Surat Textile Folding Scale with our high-quality brass cloth folding tool for textiles. Don’t miss out on the best fabric folding machine in the market! Shop now for the best deals on textile fabric folding machines.

Cloth Folder

Looking for a reliable Cloth Folder? Check out ImStarTrading.com for a wide range of options, including Brass Cloth Folder, Manual Fabric Folding Machine, and more. Shop for top-quality products like Cloth Folder, Textile Folding Kata, and Brass Clothes Folder at competitive prices. Find the perfect solution for your fabric folding needs with our selection of fabric folding machines, clips, stands, and tools. Don’t miss out on the popular Brass Cloth Folder and other essentials for efficient textile folding. Shop now and streamline your fabric folding process with the best in the industry.

Cloth Folder Clip (Kaata)

Looking for the best Cloth Folder Clip (Kaata) for your textile folding needs? Look no further than ImStarTrading.com! Our Brass Cloth Folder is the perfect solution for manual fabric folding, with options like a Cloth Folder Kaata stand for added convenience. Get your Brass Cloth Folder Clip and textile folding machine stand today!

Cloth Folder clips

Looking for Cloth Folder clips? Find manual fabric folding machines, brass cloth folders, and textile folding equipment at ImStarTrading.com. Explore a variety of fabric folding solutions including fabric folding clips, brass cloth folding stands, and more. Shop now for the most popular textile cloth folder brackets and brass cloth folder clips. Get the best deals on Kapda folding machines and manual textile clothing fabric folding machines in India. Browse our selection of fabric double folding machines and clothes folding machines for home use. Upgrade your fabric folding process with high-quality equipment at ImStarTrading.com.

Cloth folding machine

Looking for a Cloth Folding Machine? Find the best selection at ImStarTrading.com including Brass Cloth Folders, Manual Fabric Folding Machines, and more. Shop now for the best deals on textile folding equipment and accessories.

Clothes Folder

Looking for a reliable Clothes Folder? Check out ImStarTrading.com for a wide range of options including Brass Cloth Folders, Manual Fabric Folding Machines, Cloth Folder Kaata, and more. Get the best deals on clothing fabric folding machines and textile folding equipment today. Shop now for your textile folding needs!

clothes folding machine for home

Looking for a clothes folding machine for home? Visit ImStarTrading.com for a variety of options including the popular Brass Cloth Folder and Manual Fabric Folding Machine. Find the best clothes folding machine for home at competitive prices in India. Shop now for textile folding machines, fabric folding solutions, and more. Explore our wide range of products including fabric folding machine, textile folding machine, and manual textile clothing fabric folding machine. Get the best deals on fabric folding machine price and Kapda folding machine price. Buy now for efficient and convenient fabric folding solutions for your home textile needs.

clothes folding machine price in india

Looking for a clothes folding machine in India at ImStarTrading.com? Find the best deals on Brass Cloth Folder, Manual Fabric Folding Machines, and more. Shop for textile folding machines and fabric folding solutions at competitive prices. Check out the latest models of fabric folding machines and manual textile clothing fabric folding machines in India. Get your hands on popular Brass Cloth and Folding Tools for textiles. Buy now to streamline your fabric folding process efficiently!

Clothes Pegs – Brass Clothes Folder

Looking for high-quality brass clothes folders and manual fabric folding machines? Check out ImStarTrading.com for a wide range of options including the Brass Cloth Folder, Cloth Folder Kaata, and Textile Folding Kata. Our products include Brass Cloth Folding Stands, Fabric Folding Clips, and Manual Textile Clothing Fabric Folding Machines. Shop now for the best prices on these essential textile folding tools.

clothing fabric folding machine

Looking for a reliable clothing fabric folding machine for your textile business? Check out the wide range of options available at ImStarTrading.com, including Brass Cloth Folder, Manual Fabric Folding Machine, and Textile Folding Machine Stand. Find the perfect solution for your fabric folding needs, with options like brass clothes folding machine, fabric double folding machine, and more. Shop now for the best deals on textile folding equipment and accessories.

fabric double folding machine

Find the best fabric double folding machine at ImStarTrading.com. Our Brass Cloth Folder and Manual Fabric Folding Machine are perfect for efficiently folding textiles. Explore our Cloth Folder Kaata and Textile Folding Kata with Brass Cloth Folding Stands and Tools. Shop for Brass Clothes Folder clips and Fabric Folding Clips for easy fabric folding. Discover our range of fabric folding machines, including manual and textile clothing fabric folding machines. Get the most popular textile cloth folder brackets and Surat textile folding scales. Upgrade to a fabric folding solution with our high-quality machines today.

Fabric Folding Clips

Looking for the best fabric folding clips? Visit ImStarTrading.com for a variety of options including brass cloth folders, manual fabric folding machines, and more. Find the perfect solution for your textile folding needs with our wide range of products. Don’t miss out on the popular brass cloth folder clips and other textile folding tools available at competitive prices. Shop now and streamline your fabric folding process with ease!

fabric folding machine

Looking for a reliable fabric folding machine? Check out the latest collection of fabric folding machines at ImStarTrading.com. Our range includes Brass Cloth Folder, Manual Fabric Folding Machine, Textile Folding Kata, and more. Shop now for quality fabric folding solutions at great prices. Don’t miss out on our popular Brass Cloth Folder and other textile folding equipment. Visit us today to find the perfect fabric folding machine for your needs.

fabric folding machine manufacturers

Looking for fabric folding machine manufacturers at ImStarTrading.com? Check out our range of Brass Cloth Folder, Manual Fabric Folding Machine, Cloth Folder, Textile Folding Kata, and more. Get the best fabric folding solutions with fabric folding machine manufacturers. Visit us now to find the perfect fabric folding machine for your textile needs. Shop now for Brass Clothes Folder, Kapda folding machine, and more at affordable prices!

fabric folding machine price

Looking for a reliable fabric folding machine at an affordable price? Shop at ImStarTrading.com for a variety of options including Brass Cloth Folders, Manual Fabric Folding Machines, and more. Find the perfect solution for textile folding with our range of products such as Fabric Folding Clips and Textile Folding Machines. Get the best deals on Kapda folding machines, textile fabric folding machines, and other popular options. Visit us now to explore our selection of fabric folding machines at competitive prices!

Fabric Folding Machine Stand

Looking for a reliable Fabric Folding Machine Stand? Look no further than ImStarTrading.com! Our Brass Cloth Folder and Manual Fabric Folding Machine are perfect for all your textile folding needs. From Textile Folding Kata to Fabric Folding Machine Stand, we have you covered. Check out our Brass Cloth Folding Stand for efficient and precise folding. Don’t miss out on our popular Brass Cloth Folder clips for a seamless folding experience. Shop now for the best fabric folding solutions!

fabric folding solution

Looking for an efficient fabric folding solution? Check out ImStarTrading.com for a range of options, including Brass Cloth Folder, Manual Fabric Folding Machine, and Textile Folding Kata. Our products, such as Brass Clothes Folding Machine and Fabric Folding Clips, are perfect for textile manufacturers and fabric wholesalers. Find the best fabric folding machine for your needs at an affordable price. Visit us today!

folding machine textile

Looking for a high-quality folding machine for textiles? Check out our selection of Manual Fabric Folding Machines at ImStarTrading.com. Our Brass Cloth Folders and Textile Folding Machines are perfect for efficient fabric folding. Find the best Textile Cloth Folder Brackets and Brass Cloth Folder Clips for your needs. Browse our range of fabric folding solutions, including fabric folding machine manufacturers and fabric folding machine price options. Don’t miss out on our popular Brass Clothes Folder and textile fabric folding machine models. Shop now for the best Kapda folding machine price in india and Manual Textile Clothing Fabric Folding Machines near you.

Full Brass Cloth Folders

Looking for the best Full Brass Cloth Folders? Check out ImStarTrading.com for a wide range of options including Manual Fabric Folding Machines, Cloth Folder Kaata, Textile Folding Kata, and more. Our Brass Cloth Folders are perfect for textiles and clothing fabrics, with options like Brass Cloth Folder Clips and Fabric Folding Machines. Shop now for the most popular textile cloth folder brackets and Surat textile folding scales. Find the perfect solution for your fabric folding needs at ImStarTrading.com. Get the best prices on Kapda folding machines and manual textile clothing fabric folding machines in India. Shop now for the top textile fabric folding machines and equipment.

Kapda folding machine price

Looking for a Kapda folding machine at an affordable price? Check out ImStarTrading.com for the best deals on Brass Cloth Folder, Manual Fabric Folding Machine, and more. Get top-quality textile folding equipment like the popular Brass Cloth Folder and textile fabric folding machine at competitive prices. Find the perfect solution for fabric folding with our manual textile clothing fabric folding machine. Shop now and streamline your cloth folding process with ease!

Kapda folding machine price in india

Looking for the best Kapda folding machine price in India? Visit ImStarTrading.com for a wide range of options including Brass Cloth Folder, Manual Fabric Folding Machine, Cloth Folder, and more. Get the most popular textile cloth folder brackets and brass cloth folding tools at affordable prices. Find manual textile clothing fabric folding machine manufacturers and shop for the best deals on fabric folding machines. Get the perfect solution for fabric folding with our high-quality products. Explore now!

Kapde fold karne ki Machine

Looking for a reliable Kapde fold karne ki Machine? Explore a wide range of options at ImStarTrading.com, including Brass Cloth Folder, Manual Fabric Folding Machine, and Cloth Folder. Find the perfect solution for all your fabric folding needs with our high-quality and durable machines. Shop now for the best deals on textile folding equipment and accessories.

Manual Fabric Folding Machine

Looking for a manual fabric folding machine? Look no further than ImStarTrading.com! Our brass cloth folder is perfect for all your textile folding needs. From cloth folder kaata to textile folding kata, we’ve got you covered. Our manual fabric folding machine stand is top-of-the-line, offering precision and durability. Get your hands on our brass cloth folding stand today!.rfold karne ki Machine and more. Shop now for the best fabric folding solutions!

manual folding machine

Looking for a manual folding machine for your textile business? Visit ImStarTrading.com for top-quality Brass Cloth Folder, Manual Fabric Folding Machine, and more. Get the best deals on textile folding equipment and fabric folding machines. Shop now!

Manual Textile Clothing Fabric Folding Machine

Looking for a Manual Textile Clothing Fabric Folding Machine? Check out ImStarTrading.com for the best selection of Brass Cloth Folders, Manual Fabric Folding Machines, and more. Our Manual Textile Clothing Fabric Folding Machine is perfect for fabric double folding, with options like Fabric Folding Clips and a Fabric Folding Machine Stand. Get the best deals on manual textile folding machines and Brass Cloth Folders at ImStarTrading.com today!

Manual textile clothing fabric folding machine in india

Looking for a manual textile clothing fabric folding machine in India? Visit ImStarTrading.com for a wide range of options including Brass Cloth Folder, Manual Fabric Folding Machine, Cloth Folder clips, and more. Find the best deals on Manual Textile Clothing Fabric Folding Machine and get the most popular textile cloth folder brackets at competitive prices. Shop now for the perfect solution for fabric folding in the textile industry.

Manual textile clothing fabric folding machine manufacturers

Looking for manual textile clothing fabric folding machine manufacturers? Look no further than ImStarTrading.com! We offer a range of brass cloth folders, manual fabric folding machines, cloth folders, and more. Our products are perfect for textile folding, fabric double folding, and clothing fabric folding. Check out our manual textile clothing fabric folding machines today!

Manual textile clothing fabric folding machine near me

Looking for a manual textile clothing fabric folding machine near you? Look no further! At ImStarTrading.com, we offer a wide range of options including Brass Cloth Folder, Manual Fabric Folding Machine, Cloth Folder, and more. Get the best manual textile clothing fabric folding machine for your needs at a great price. Visit us today!

Manual textile clothing fabric folding machine price

Looking for a manual textile clothing fabric folding machine near you? Look no further! At ImStarTrading.com, we offer a wide range of options including Brass Cloth Folder, Manual Fabric Folding Machine, Cloth Folder, and more. Get the best manual textile clothing fabric folding machine for your needs at a great price. Visit us today! Find the most popular textile cloth folder brackets, Surat textile folding scale, and used fabric folding machines.

Manual textile clothing fabric folding machine price in india

Looking for a Manual Textile Clothing Fabric Folding Machine at the best price in India? Check out ImStarTrading.com for Brass Cloth Folder, Manual Fabric Folding Machine, Cloth Folder, and more. Get the most popular textile cloth folder brackets and surat textile folding scale. Find the best deals on manual folding machines for textiles at ImStarTrading.com. Shop now!

manual textile folding machine

Looking for a manual textile folding machine for your fabric manufacturing needs? Visit ImStarTrading.com for a wide range of options including Brass Cloth Folders, Manual Fabric Folding Machines, and Cloth Folder clips. Find the best deals on manual textile folding machines and improve your fabric folding process today!

Most Popular Textile Cloth Folder Brackets

Looking for the most popular textile cloth folder brackets? Look no further than ImStarTrading.com! Our brass cloth folder, manual fabric folding machine, and textile folding kata are top choices in the industry. Shop our selection of brass cloth folder clips, fabric folding machines, and clothing fabric folding machines for all your textile folding needs. With a wide range of options and competitive prices, ImStarTrading.com is your one-stop shop for textile folding solutions. Visit us today to find the perfect cloth folder for your needs!

Popular Brass Cloth Folder

Looking for a popular brass cloth folder? Check out the manual fabric folding machine at ImStarTrading.com. Our brass cloth folder is a must-have tool for textile enthusiasts, providing precise and efficient folding for your clothing fabrics. With features like cloth folder clips and a sleek brass design, this folding machine is a game-changer for your home or garment manufacturing needs. Find the most popular textile cloth folder brackets and Surat textile folding scales here at ImStarTrading.com. Shop now for the best prices on fabric folding machines and get your clothing fabrics neatly folded in no time.

non automatic fabric folding machine

Looking for a non-automatic fabric folding machine? Check out ImStarTrading.com for a wide range of options, including brass cloth folders, manual fabric folding machines, and more. Find the perfect textile folding solution with our popular brass cloth folders and clothing fabric folding machines. Shop now for the best prices on fabric folding equipment and textile folding machines. Visit us today!

Popular Brass Cloth

Looking for the most popular brass cloth folder for your textile folding needs? Look no further than ImStarTrading.com. Our manual fabric folding machine, also known as the cloth folder or “Kaata,” is a top-of-the-line tool for efficient textile folding. With features like brass cloth folding stands and clips, this brass cloth folder is a must-have for any textile industry professional. Get your hands on the most popular textile cloth folder on the market today. Visit ImStarTrading.com to find the best deals on fabric folding machines and more.

Surat Textile Folding Scale

At ImStarTrading.com, find the most popular Surat Textile Folding Scale including brass cloth folders, manual fabric folding machines, cloth folders, and more. Shop for brass textile cloth folders and manual textile clothing fabric folding machines at competitive prices. Explore our wide range of fabric folding solutions, including fabric folding clips, folding stands, and more. Visit us now for the best deals on textile folding equipment.

textile fabric folding machine

Looking for a reliable and efficient textile fabric folding machine? Look no further than ImStarTrading.com! Our Brass Cloth Folder, Manual Fabric Folding Machine, and Cloth Folder Kaata are perfect for all your textile folding needs. With features like Brass Cloth Folding Stand and Fabric Folding Clips, our machines make folding textiles a breeze. Check out our selection of textile fabric folding machines at ImStarTrading.com today!

textile folding equipment

Looking for high-quality textile folding equipment? Visit ImStarTrading.com for a wide range of options including Brass Cloth Folder, Manual Fabric Folding Machine, and more. Find the best textile folding solutions with keywords like textile fabric folding machine, textile folding equipment, and textile folding machine. Shop now for fabric folding machine, cloth folder, and brass clothes folder, available at competitive prices.

textile folding machine

Looking for a reliable and efficient textile folding machine? Look no further! Visit ImStarTrading.com for a wide range of options including the popular Brass Cloth Folder, Manual Fabric Folding Machine, and various Cloth Folding solutions. Explore our collection of fabric folding machines at competitive prices, including Brass Clothes Folder, clothing fabric folding machine, and more. Find the perfect textile folding machine for your needs at ImStarTrading.com today!

than folding machine

Looking for a high-quality and efficient cloth folding machine? Look no further than ImStarTrading.com! Our brass cloth folder and manual fabric folding machines are perfect for textile industry professionals looking for a reliable and durable solution. With features like Cloth Folder Kaata, Textile Folding Kata, and Full Brass Cloth Folders, our machines are designed to streamline your fabric folding process. Don’t settle for subpar folding machines – choose ImStarTrading.com for all your fabric folding needs. Shop now for the best prices on brass clothes folders, fabric folding clips, and more!

used fabric folding machine

Looking for a used fabric folding machine? Visit ImStarTrading.com for a variety of options including brass cloth folders, manual fabric folding machines, and textile folding machines. Find the best deals on fabric folding equipment, with options like fabric clips, stands, and tools for efficient cloth folding. Check out popular options like the brass cloth folder and manual textile clothing fabric folding machines. Upgrade your fabric folding process with a reliable and cost-effective solution today!

Fabric Ghadi Kata For Textile

Looking for a reliable Fabric Ghadi Kata solution for your textile business? Check out ImStarTrading.com for a wide range of options including Brass Cloth Folders, Manual Fabric Folding Machines, Cloth Folder Kaata, and more. Find the best deals on Textile Folding Kata and Brass Cloth Folding Stands. Explore our collection of Brass Clothes Folding Tools and Fabric Folding Machines at competitive prices. Shop now for the most popular textile cloth folder brackets and Surat Textile Folding Scales. ToolStrip=Page1,Most Popular Textile Cloth Folder Brackets,Popular Brass Cloth,Popular Brass Cloth Folder,Surat Textile Folding Scale,textile fabric folding machine,textile folding equipment,textile folding machine,than folding machine,used fabric folding machine.

Cloth Folder Kata Metar – Fabric Folding Ghodi Stand Kanta

Looking for a reliable fabric folding solution for your textile factory? Look no further than the Cloth Folder Kanta Metar – Fabric Folding Ghodi Stand Kanta. This manual fabric folding machine is perfect for folding a variety of fabrics such as Terrycot, Choli, Kurtis, Sarees, and more. Improve efficiency and productivity in your factory with this versatile fabric folding stand. Order now and streamline your fabric folding process with ease.

Brass Cloth Folder in Delhi, Noida, Gurgaon, India

Looking for a reliable Brass Cloth Folder in Delhi, Noida, Gurgaon, India? Check out our range of high-quality Brass Cloth Folder, Folding Kata, and Textile Folder Stand. Our Fabric Folding Machine is perfect for Textile Mills and Garment Industries. Buy now from ImStarTrading for efficient cloth folding solutions.

Brass Cloth Folder – Shanti Mohalla in Delhi

Looking for a reliable Brass Cloth Folder in Shanti Mohalla? Look no further than our range of high-quality folding machines, including kanta, kata, metar, godi, and more. Our Brass Cloth Folder is perfect for textile mills and garment industries, providing efficiency and precision in fabric folding. Choose from a variety of options including manual fabric folding machines, Brass Cloth Folder clips, and textile folding stands. Trust ImStarTrading for all your textile fabric folding needs.

Top Brass Cloth Folder Price List in India

Brass Cloth Folder – Price Range

| Cloth Folder | Min Price | Max Price |

|---|---|---|

| ₹1 | ₹1489 | |

| Manual Fabric Folding Machine | ₹490 | ₹14490 |

| Popular Brass Cloth | ₹1779 | ₹42319 |

| Textile Folding Machine | ₹199 | ₹1319 |

| Brass Material – M/S Cloth Folder | ₹2018 | ₹9604 |

| Brass Material – Steel Cloth Folder | ₹56671 | ₹56671 |

| Brass Material – Brass Cloth Folder | ₹689 | ₹2200 |

| Brass Material – Iron Cloth Folder | ₹4739 | ₹9020 |

| Cloth Folder Capacity Range – 60 To 100 Folds Cloth Folder | ₹1650 | ₹1999 |

| Cloth Folder Capacity Range – 125 To 150 Folds Cloth Folder | ₹2299 | ₹2499 |

| Cloth Folder Capacity Range – 200 To 250 Folds Cloth Folder | ₹3359 | ₹3599 |

| Cloth Folder Capacity Range – 300 To 350 Folds Cloth Folder | ₹3799 | ₹4999 |