fabric folding machine

Discover the transformative role of fabric folding machines in the textile industry. These advanced machines enhance efficiency and precision, handling various fabrics and folding techniques. Modern innovations like automated controls and precision sensors ensure high-quality and consistent folds, reducing labor costs and increasing productivity. Learn how these machines revolutionize textile manufacturing with features like customizable folding patterns and user-friendly interfaces.

-

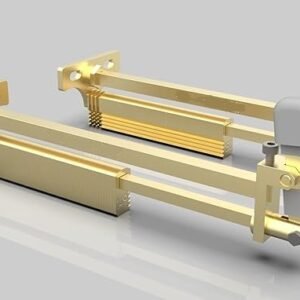

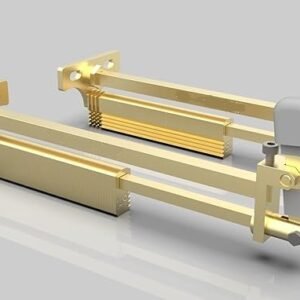

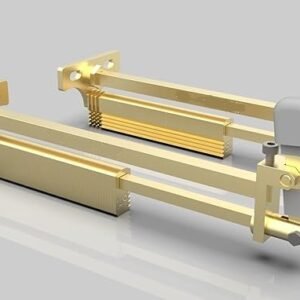

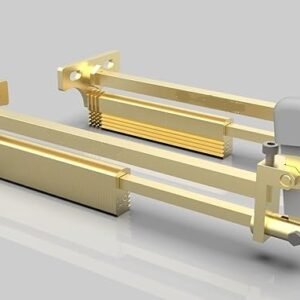

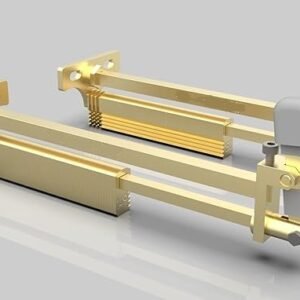

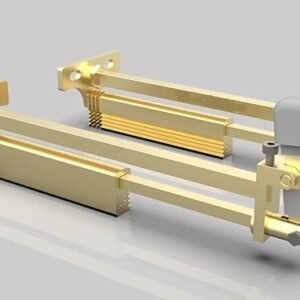

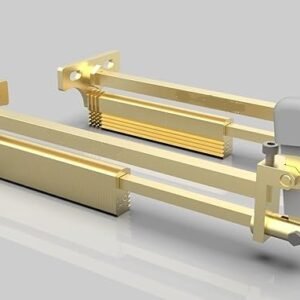

Brass Cloth Folder with Bracket: Effortless Organization for Wrinkle-Free Clothes (100 Folds)

- ₹2,999.00

- Looking to buy a Brass Cloth Folder with Bracket online at the best prices in India? Look no further than ImStarTrading! Our Brass Cloth Folder is the perfect tool for textiles, with features like Cloth Folder clips and a manual folding machine for clothing fabrics. Find popular Brass Cloth Folder options and more at ImStarTrading today!

- Add to cart

The Ultimate Guide to Fabric Folding Machines: Efficiency and Innovation in Textile Processing

Introduction to Fabric Folding Machines

Fabric folding machines play a critical role in the textile industry, streamlining the process of folding fabrics with precision and speed. These machines are designed to handle a wide variety of fabrics, ranging from delicate silks to robust cottons and synthetics, ensuring that each piece is folded uniformly. The basic mechanics involve a series of rollers, guides, and folding arms that work in tandem to achieve the desired fold. Different folding techniques, such as Z-fold, roll fold, and accordion fold, can be programmed into the machines, allowing for versatility in handling diverse textile requirements.

The advent of fabric folding machines has revolutionized textile processing by drastically reducing the need for manual labor. Manual folding not only is time-consuming but also prone to inconsistencies and errors. By automating this process, fabric folding machines ensure a consistent and high-quality finish, which is crucial for subsequent production stages like cutting, sewing, and packaging. The increased efficiency brought by these machines translates to higher productivity and cost savings for textile manufacturers.

Historically, the development of fabric folding machines can be traced back to the early 20th century, when the textile industry began to seek more efficient methods of production. Early models were rudimentary and required significant manual oversight. However, with the advent of advanced technologies such as robotics, sensors, and computer programming, modern fabric folding machines have become highly sophisticated. They now offer features like automatic fabric detection, precise alignment, and adjustable folding patterns, making them indispensable tools in contemporary textile manufacturing.

Overall, fabric folding machines are essential for enhancing the efficiency and consistency of textile processing. They not only reduce labor costs but also improve the quality of the folded fabric, making them a valuable asset in the textile industry. As technology continues to advance, we can expect these machines to become even more efficient and versatile, further solidifying their importance in textile production.

Key Features and Innovations in Modern Fabric Folding Machines

Modern fabric folding machines have revolutionized the textile industry with their advanced features and innovations. These machines are equipped with automated control systems that significantly enhance operational efficiency. Precision sensors are another pivotal feature, ensuring that each fold is accurate and consistent, thereby improving the quality of the final product. Customizable folding patterns allow manufacturers to meet diverse customer demands, further adding to the versatility of these machines.

An essential aspect of contemporary fabric folding machines is their user-friendly interfaces. These interfaces are designed to be intuitive, enabling operators to easily navigate through various functions and settings. The integration of sophisticated software allows for seamless operation and maintenance, reducing downtime and increasing overall productivity. Additionally, these machines often come with diagnostic tools that can quickly identify and address any issues, thereby minimizing operational disruptions.

The impact of these technological advancements on productivity cannot be overstated. Automated systems and precision sensors work in tandem to accelerate the folding process, leading to higher throughput rates. This increase in productivity translates to cost-effectiveness, as manufacturers can produce more units in less time while maintaining high-quality standards. The reduction in labor costs and material wastage further contributes to the overall profitability of using modern fabric folding machines.

Case studies provide real-world evidence of the benefits brought by these innovations. For example, a leading textile manufacturer recently implemented a new fabric folding machine with state-of-the-art automated controls and precision sensors. The result was a 30% increase in production speed and a 20% reduction in material wastage, leading to substantial cost savings and improved product quality. Such examples underscore the transformative impact of modern fabric folding machines on the textile industry.