manual folding machine

Discover the essential role of manual folding machines in various industries, including printing, packaging, and office environments. Learn about the different types, advantages, and how to choose and operate these cost-effective and user-friendly tools. Ensure precise and consistent folds for all your professional needs with our comprehensive guide.

-

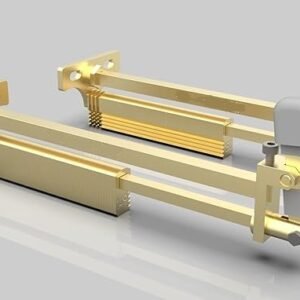

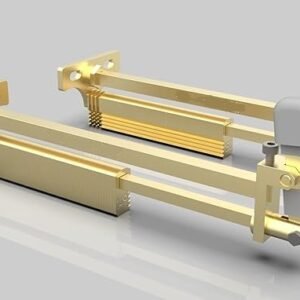

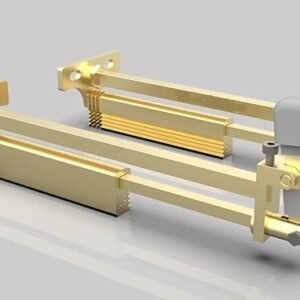

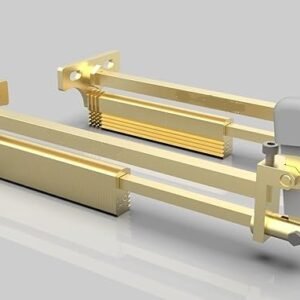

Brass Cloth Folder with Bracket: Effortless Organization for Wrinkle-Free Clothes (100 Folds)

- ₹2,999.00

- Looking to buy a Brass Cloth Folder with Bracket online at the best prices in India? Look no further than ImStarTrading! Our Brass Cloth Folder is the perfect tool for textiles, with features like Cloth Folder clips and a manual folding machine for clothing fabrics. Find popular Brass Cloth Folder options and more at ImStarTrading today!

- Add to cart

The Ultimate Guide to Manual Folding Machines: Efficiency and Precision in Your Hands

Introduction to Manual Folding Machines

Manual folding machines are essential tools in various industries, designed to fold paper and other materials with precision and efficiency. These machines are particularly prevalent in sectors such as printing, packaging, and office environments, where accurate and consistent folding is crucial. A manual folding machine facilitates tasks that would otherwise be time-consuming and prone to human error, making them indispensable in many professional settings.

There are several types of manual folding machines available on the market, each catering to different needs and capacities. Some common types include the bone folder, used primarily for small-scale tasks, and the more robust hand-operated folding machines designed for larger volumes and thicker materials. The size and capability of a manual folding machine can vary significantly, from compact desktop models ideal for office use to larger, more industrial machines suited for heavy-duty applications.

One of the key advantages of using manual folding machines is their cost-effectiveness. Unlike automated folding machines, manual versions do not require electricity, thereby reducing operating costs. Moreover, they are generally more affordable to purchase and maintain. Ease of use is another significant benefit; manual folding machines are designed to be user-friendly, requiring minimal training to operate effectively. This simplicity extends to maintenance, as these machines typically have fewer mechanical components that can wear out or malfunction.

The history of manual folding machines dates back to early bookbinding practices where artisans used simple tools to create precise folds. Over time, these tools evolved into more sophisticated devices, incorporating features that improved accuracy and ease of use. Today’s manual folding machines are the result of centuries of innovation, combining traditional craftsmanship with modern engineering to meet the demands of contemporary industries.

Understanding the role and functionality of manual folding machines is crucial for anyone involved in printing, packaging, or office administration. These machines not only enhance productivity but also ensure the consistency and quality of the folded materials, making them a valuable asset in any professional environment.

How to Choose and Operate a Manual Folding Machine

When selecting a manual folding machine, several critical factors must be considered to ensure it meets your specific needs. First, evaluate the types of materials you will be working with. Different machines are designed to handle various materials such as paper, cardboard, or metal sheets. Understanding your material requirements will help you choose a machine with the appropriate strength and durability.

Next, consider the folding patterns you need. Manual folding machines come with different configurations for creating specific folds, such as single folds, bi-folds, and tri-folds. Ensure the machine you select can accommodate the particular folding patterns required for your projects.

Capacity is another vital factor. Assess the volume of work you intend to process to choose a machine with the right capacity. Machines with higher capacity can handle larger batches, making them suitable for high-volume operations, while smaller machines are ideal for lower-volume, precise tasks.

Once you have chosen the appropriate manual folding machine, setting it up and operating it correctly is crucial. Begin by reading the manufacturer’s manual thoroughly. Position the machine on a stable surface to ensure it remains steady during operation. Adjust the folding guides and settings according to the specific fold type and material thickness. It is essential to perform a test run with a sample piece to verify the settings before proceeding with the actual work.

Safety precautions are paramount. Always wear appropriate safety gear, such as gloves and safety glasses. Keep fingers and loose clothing away from moving parts. Regularly inspect the machine for any signs of wear or damage, and address any issues promptly to prevent accidents.

Best practices for achieving precise folds include maintaining a clean work area and ensuring the material is free from dust and debris, which can affect the quality of the fold. Consistently check the alignment and adjust the settings as necessary to achieve the desired precision.

Maintaining your manual folding machine is key to its longevity and optimal performance. Regularly lubricate moving parts, follow the manufacturer’s maintenance schedule, and store the machine in a dry, clean environment. By adhering to these guidelines, you can ensure your manual folding machine remains efficient and precise for years to come.